The inventory management system is essential for maintaining easy operations and ensuring consumer satisfaction in today’s fast-paced enterprise surroundings. An Inventory Management System (IMS) serves as the spine for companies by offering solid solutions to track, manage, and optimize their inventory. With the increasing complexity of supply chains and rising user expectations for well-timed delivery, the function of IMS has yet to be more crucial than ever in logistics and distribution pipeline. An IMS integrates various aspects of inventory control, offers real-time visibility into inventory levels, automates processes, and streamlines order management. By leveraging technologies such as barcode scanning, RFID, and data analytics, these systems ensure accuracy and efficiency in inventory tracking and control.

One of its key benefits is the significant reduction in operational costs. From small retailers to giant multinational enterprises, adopting inventory management software solutions allows businesses to keep better stock levels, lessen operational charges, and improve transport performance.

The importance of IMS extends mere inventory control; it impacts the enterprise’s overall performance. This blog explores how effective inventory management can extend profitability, increase consumer satisfaction levels, and give an aggressive advantage to businesses. As businesses continue to evolve, the need for robust and adaptable inventory monitoring systems will become increasingly imperative.

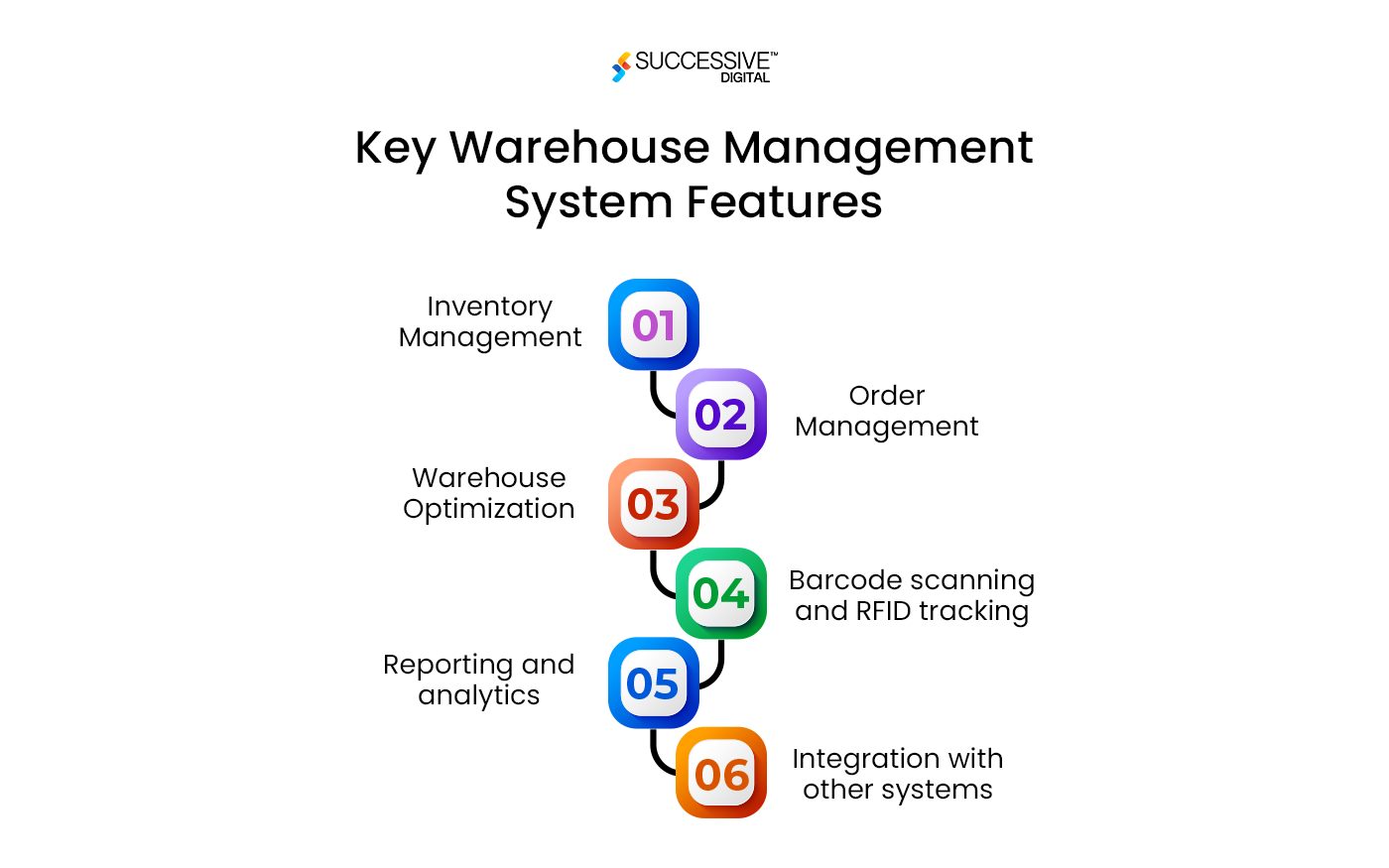

Features of Inventory Management Systems

Real-Time Inventory Tracking:

IMS offers the convenience of tuning inventory levels in real-time, providing accurate and up-to-date data on stock availability. This feature ensures that the right amount of stock is always on hand, preventing stockouts and overstocking and thereby reassuring teams of the system’s reliability.

Order Management:

Inventory management software integrates with order management systems to streamline the order fulfillment process. It tracks orders from placement to delivery, ensuring that clients receive their merchandise on time. This function additionally helps manage returns and partial shipments and is considered the most crucial component for digital logistics and distribution solutions.

Barcode and RFID Scanning:

Utilizing barcode and RFID technology, the inventory monitoring system complements the accuracy and velocity of stock monitoring. These technologies facilitate quick and unique data entry, lowering the chance of errors and improving efficiency.

Automated Replenishment:

An advanced inventory management system, with its ability to analyze historical data and current demand, can efficiently automate the replenishment process. By generating purchase orders when inventory levels fall below a predefined threshold minimizes the risk of human error and instills confidence in the system’s ability to handle demand fluctuations.

Analytics and Reporting:

IMS offers strong analytics and reporting talents, offering insights into stock overall performance, sales developments, and demand patterns. These insights allow for data-driven decision-making and help businesses identify regions for development.

Integration with Other Systems:

Modern inventory management software solutions can integrate with other business structures, including ERP, CRM, and e-commerce platforms. This integration ensures seamless data flow and complements usual operational efficiency.

Serial Number and Lot Tracking:

For businesses handling perishable goods or merchandise with unique batch numbers, IMS provides serial number and lot monitoring capabilities. This enables handling product recalls, ensuring compliance with rules, and maintaining great control.

User Access Control:

An inventory monitoring system provides users with admission to manipulate, allowing corporations to outline roles and permissions for different users. This ensures that sensitive data are accessible for authorized employees, enhancing records security.

Mobile Access:

Many IMS solutions provide cell access via apps or mobile-friendly interfaces. This characteristic allows on-the-go inventory management, allowing users to perform tasks such as stock checks, order processing, and reporting from their mobile devices.

Types of Inventory Management Software

Inventory management software comes in numerous forms to support end-to-end visibility over stocks and streamline logistics and distribution operations. Each software caters to specific business desires and operational necessities. Understanding the types can assist businesses in choosing the proper solution for their particular requirements.

Standalone Inventory Management Software: is a perfect fit for small to medium-sized businesses. It focuses entirely on inventory capabilities, such as monitoring inventory ranges, handling orders, and producing reviews. This dedicated tool is ideal for businesses that need a straightforward solution without the added complexity of broader business control functions.

Integrated Inventory Management Software: is an asset for growing organizations. These solutions integrate inventory control with other enterprise processes like accounting, income, and buying, offering a comprehensive view of enterprise operations. This makes them more than just stock control, making them suitable for organizations that require a holistic approach to their operations.

Enterprise Resource Planning (ERP) Systems: ERP systems comprise stock management as part of a bigger suite that includes finance, HR, production, and more. They provide a unified platform for managing all enterprise factors appropriate for huge firms with complex needs.

Cloud-Based Inventory Management Software: These solutions allow users to access inventory statistics anywhere with an internet connection. They generally have subscription-based pricing and are ideal for companies seeking scalability and decreased IT overhead.

Open-Source Inventory Management Software: Open-source solutions provide customizable inventory control capabilities. They are perfect for agencies with in-residence IT know-how searching out a cost-powerful and adaptable solution.

Warehouse Management Systems (WMS): WMSs specialize in warehouse operations, including storage, choosing, packing, and delivery. They offer superior capabilities, which include automatic workflows and real-time monitoring, making them ideal for big-scale warehouse environments.

Conclusion

An effective inventory management system is integral for organizations seeking to streamline inventory processes, improve operational efficiency, and improve user satisfaction. With expertise in the capabilities, types, and pros and cons of inventory monitoring systems, companies can make informed choices about imposing the right solution for their business desires. While the initial funding and integration issues might also appear challenging, the long-term potential of advanced accuracy, performance, and data-driven insights can considerably outweigh the drawbacks, making IMS an asset for any enterprise growth.