Inventory management technology plays a major role in the success of any organization. A comprehensive process that includes ordering, packaging, and efficient use of a company’s inventory is not just limited to inventory management. Poor inventory management can lead to problems in effective Logistics & Distribution operations, such as overstocking, stockouts, loss of sales, and an increase in operating costs, which can affect profits and customer experience. Businesses have relied on processes that led to human error in the past. Warehouse inventory solutions have become an important tool to solve these problems with the advancement of technology. The software helps businesses make informed decisions, reduce costs, and increase overall profitability by providing instant data and insights. Major changes in the way businesses manage inventory and resources have been made by the evolution of this technology.

Key Challenges in Inventory Management

-

Inaccurate Stock Levels:

One of the most unusual issues in ecommerce inventory management is preserving accurate inventory levels. Inaccuracies can cause stockouts, excess stock, and in the long run, lost sales, or increased cost to shipping.

-

Demand Forecasting:

Predicting customer demand is inherently difficult, and poor demand forecasting can bring about either overstocking or stockouts, each of them having financial implications.

-

Manual Errors:

Human error in manual warehouse inventory solutions can lead to discrepancies between actual and recorded stocks, affecting the accuracy of financial reporting and decision-making.

-

Time-Consuming Processes:

Manual inventory management is time-consuming, involving tedious data entry, everyday audits, and physical counting, that may detract from other vital business operations.

-

Lack of Real-Time Information:

Without real-time inventory tracking, companies struggle to make better and on-time decisions, main reason for inefficiencies in ordering, manufacturing, and customer service.

-

Supply Chain Disruptions:

Challenges in the supply chain, which include delays or disruptions, can critically impact stock levels, leading to shortages or excesses of goods at warehouse.

How Technology Addresses Inventory-Related Issues:

Real-Time Inventory Tracking:

Inventory management technology allows businesses to monitor stock levels in real time. This means that as quickly as goods are bought or added to stock, the software automatically updates the stock levels, ensuring that the information and data is always accurate. Real-time tracking reduces the threat of stockouts and extra stock, ensuring seamless logistics and distribution as businesses can reorder inventory straight away while ranges fall beneath a certain threshold.

Improved Demand Forecasting:

Inventory tracking software often features demand forecasting tools that leverage historical patterns, marketplace developments, and different variables to anticipate future demand. This computerized feature enables warehouse teams to control their inventory correctly, minimizing the chances of overstocking or understocking.

Enhanced Reporting and Analytics:

Advanced ecommerce inventory management provides businesses with specified reports and analytics on inventory levels, sales developments, and more. These insights allow businesses to select patterns, optimize stock levels, and improve efficiency. Customizable dashboards allow teams to screen vital key performance indicators (KPIs) in real-time, making it less complicated to discover problems and take corrective action early.

Reduction of Human Error:

Inventory management technology lowers the probability of human mistakes by automating statistics access and recurring procedures. By incorporating barcoding and RFID (Radio Frequency Identification) structures with warehouse stock solutions, companies can further lessen tracking errors. This integration leads to extra unique stock facts, enhancing confidence and reliability in selection-making.

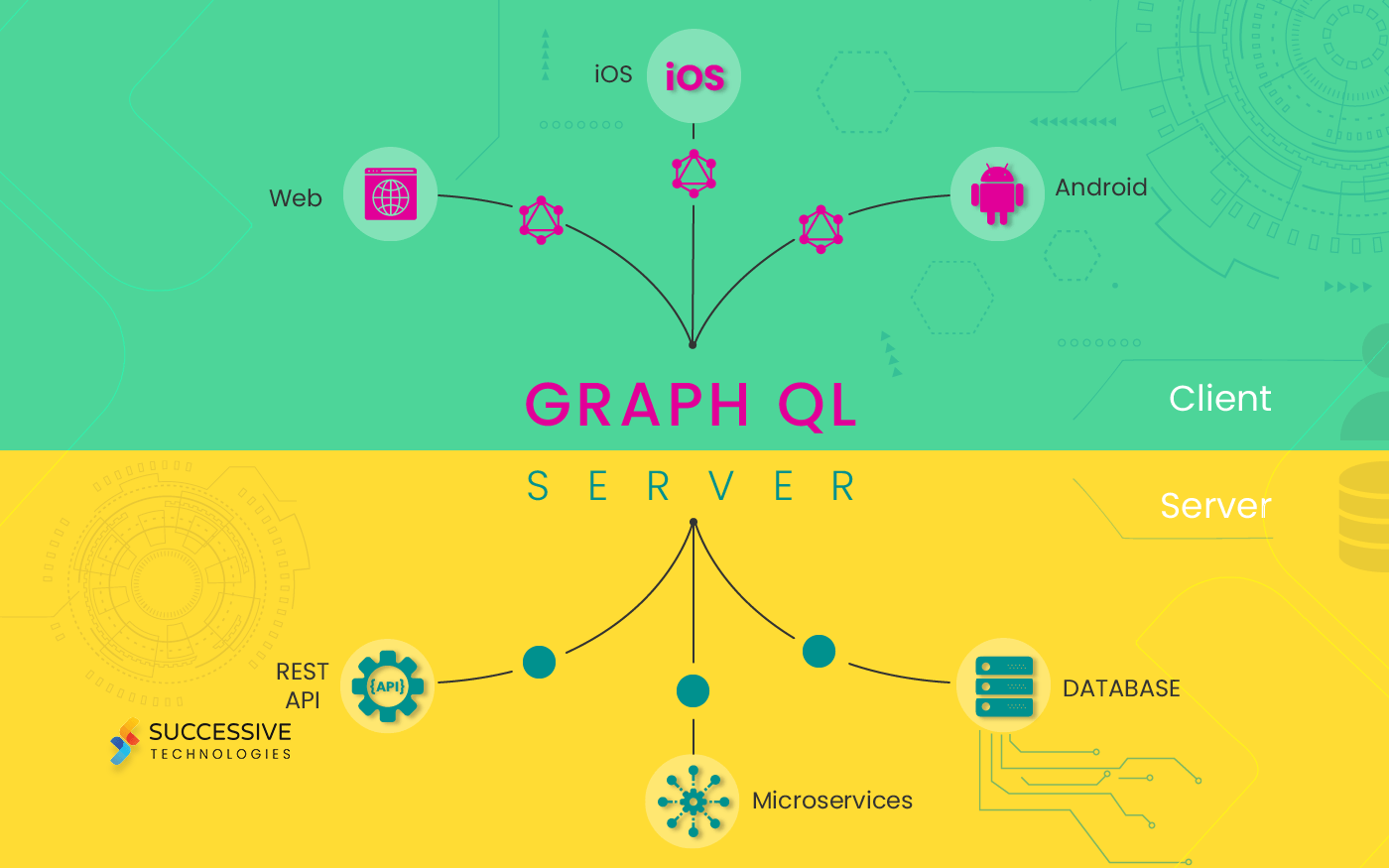

Integration with Other Business Systems:

Present-day automated inventory management software can be integrated with different business systems, including accounting, ERP, and e-commerce platforms. This ensures that stock information is synchronized throughout all departments, leading to better coordination and advanced performance. For example, integrating stock management with accounting software ensures that financial information is automatically updated with the latest inventory data, significantly reducing the risk of discrepancies and instilling a sense of security and confidence.

Supply Chain Optimization:

Inventory management software allows organizations to optimize their supply chains by imparting visibility into each section, from providers to clients. This permits companies to discover ability bottlenecks, monitor supplier performance, and improve lead times. by streamlining the deliver chain, groups can lower operational costs, enhance customer satisfaction, and growth profitability.

Multi-Channel Management:

For businesses that sell through multiple channels, automated inventory management software offers a unified view of inventory. This ensures that stock levels are accurately reflected across all sales channels, providing business owners with peace of mind and reducing the risk of overselling or underselling.

Scalability:

As organizations grow bigger, their inventory control requirements scale to be more and more problematic. The flexibility of warehouse management solutions gives peace of thought through scaling along the enterprise. Whether coping with a small storage facility or overseeing a global delivery chain, this software may be custom-designed to deal with the business’s precise needs, making it less difficult to navigate future situations.

Improved Customer Satisfaction:

A real-time inventory management complements user satisfaction by means of making sure that products are always in inventory and ready for shipping. This reduces the likelihood of delays or backorders, ensuing in a greater and fantastic buying experience.

Conclusion

As inventory management technology evolves, it becomes increasingly more advanced and important for businesses, involving new functions and abilities that in addition enhance operations. For companies aiming to streamline their processes and scale profitability, making an investment in inventory management software program isn’t just a choice—it’s a crucial requirement.